Stand out with your brand,

upgrade to FDM 3D printing

Fit individual needs to engage the masses

We offer a comprehensive workflow for FDM 3D printing process integration:

it’s more than a production technology, it’s a partnership! stand out with your brand

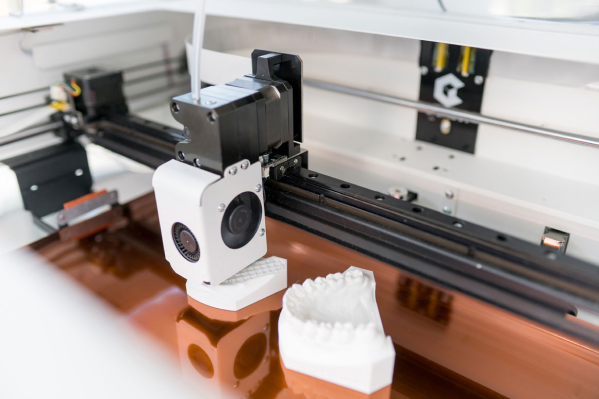

FDM-based production process development, including material specification, yield optimization, machine customization.

Dataflow implementation from the 3D model to the 3D printed product with minimum operator interaction.

3D printing workflow automation with custom CAD, slicing and machine communication tools.

Complete solution with hardware, software, materials and application engineering.

FDM-based production process development, including material specification, yield optimization, machine customization.

Dataflow implementation from the 3D model to the 3D printed product with minimum operator interaction.

3D printing workflow automation with custom CAD, slicing and machine communication tools.

Complete solution with hardware, software, materials and application engineering.

Best solution for mass customization

Get the most out of FDM 3D printing and upgrade your business in an effortless and efficient way!

Adapt easily

- flexible production process

- available for any industry

- personalized design

Increase cost-efficiency

- reduce production costs

- eliminate material waste

- reduce production time

Improve quality

- high precision printing

- greater complexity

- reduce scrap rate

Grow your business

- differentiate your products

- stand out with your brand

- get ahead of competitors

Survive or thrive

in the market?

Business owners face the challenge to keep up with industry trends: mass customization gains space in the market and personalization is key to impress customers.

Thermoplastic-based additive manufacturing is the most efficient way to address these challenges. So businesses need to introduce 3D printing to survive, but it’s not yet enough to thrive in the market. It requires a new business model and professional guidance.

The manufacturing workflow can make or break your business. Make it big with Craftbot.

It’s more than technology. It’s a partnership.

We offer an all-inclusive solution to make the technological shift easy for your

business: achieve fast results and long-term profitability!

Zero in waste,

Hero in productivity

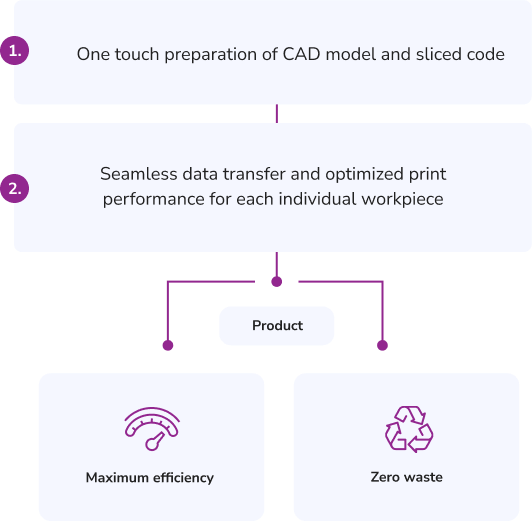

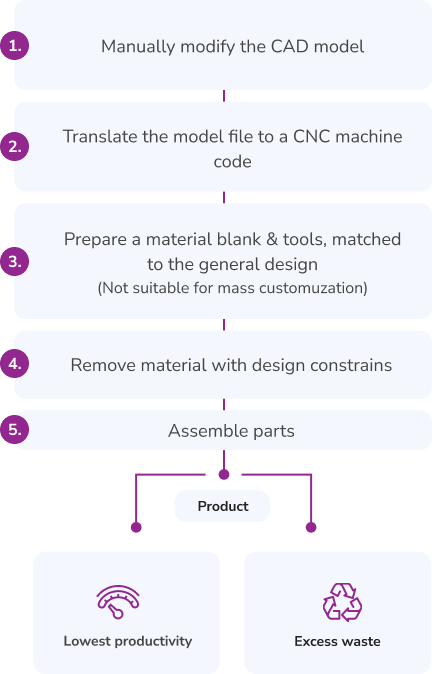

A technological shift from subtractive to additive manufacturing is not only beneficial for the planet by producing zero waste but also supports lean manufacturing to increase cost-efficiency.

Minimize waste, maximize your productivity. Optimize mass customization with us.

We make a difference

Our team provides professional guidance to help you stand out in the market and solve the challenges of custom manufacturing with ease.

Every business is unique, that’s why we offer a highly flexible technology integration service for industrial and business needs. We don’t just ask for customer feedback. We listen to it. We know what you need.

This is where we make a difference.

Get more competitive, get closer to your customers

We are all unique: our body shape, taste and individual needs. If you want to get ahead of competitors you have to get closer to your customers’ expectations.

Human-based customization

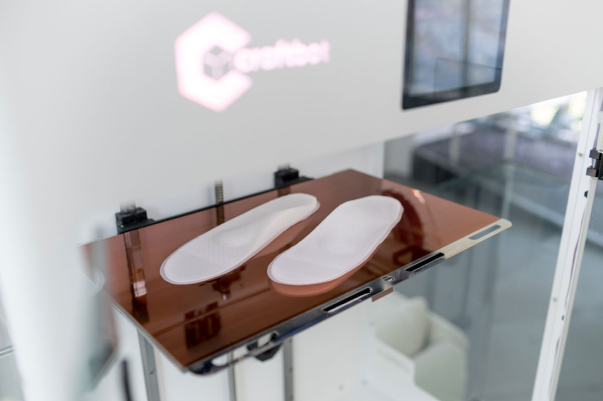

Make your customers feel comfortable in their own skin: create custom-made protective gears, helmets, shoes or medical parts.

Design-based customization

Design is not just about trends and aesthetics, it’s about taste, Fashion, furniture and the car industry can equally benefit from design customization.

Functional product customization

Any product configuration is a possible use case, especially where an extensibe object library is present.

Workpiece 3D model

Shape the future with us

Personalisation will continue to shape the consumer landscape. Our mission is to prepare businesses for this technological shift and provide them with an ecosystem that allows for a high quality and cost-efficient manufacturing workflow.

Innovation is a mindset – Impress your customers and shape the future of your business with us!

Your workflow can make or break your business.

Make it big with Craftbot.

Get an offer today!

Get closer to your clients. Get more competitive.

Frequently Asked Questions

1. What are the benefits of 3D printing for me?

3D printing offers multiple business benefits that make a compelling case for its use. These benefits are characterized by six key factors:

1) Design freedom: Parts can be optimized for their design purpose, rather than being constrained by traditional manufacturing limitations.

2) Embedded functionality: 3D printing allows for the incorporation of added functionality into a part or assembly, eliminating manufacturing steps, reducing cycle time and costs.

3) Streamlined supply chains: On-demand capabilities and point-of-use manufacturing shorten traditional supply chains, speed up delivery and reduce inventory costs.

4) Personalisation: By avoiding the burden of economies of scale, personalisation can be mass customized, enabling greater market differentiation.

5) Cost-effective manufacturing: The absence of tooling requirements eliminates one of the largest manufacturing costs, making low-volume production more cost-effective.

6) Life-cycle sustainability: Design freedom and point-of-use manufacturing allow for lighter, optimized parts that save energy and reduce environmental impact.

Overall, 3D printing opens new doors. It can save days of manufacturing cycles, remove the complexity of final assembly, create lightweight, high-strength structures, create hyper-realistic prototypes and make your business more competitive.

2. Is FDM 3D printing suitable for rapid prototyping or manufacturing?

Both. FDM printing is an essential tool to speed up the prototyping process via printing life-size, even functional models from a wide range of thermosetting polymers with controlled flexibility within hours.

If thermopolymers have a significant role in your production process however, FDM 3D printing can be the perfect choice to improve your yield or reduce the waste. Utilizing the technology, you don’t need expensive tooling and installation to make things. Due to its additive nature, it is a fast, low to medium volume manufacturing solution that does not depend on economies of scale, similar to investing in injection molding tools. This opens up new opportunities where small-scale and/or on-demand production was previously uneconomic.

It also supports distributed manufacturing, where parts can be easily printed from anywhere. For example, an airline could 3D print its own spare parts in its own maintenance facility instead of having to ship them to the manufacturer.

In terms of tooling, FDM 3D printing offers the same flexibility, as it can produce tools, fixtures, hand end tools and other manufacturing aids in a much shorter time and at a much lower cost than traditional tooling. These tools can be easily and ergonomically customized and optimized for the operator, rather than designed for production. The use of strong thermoplastics instead of metal allows them to be lighter and easier to use, increasing task efficiency and reducing cycle times.

3. How costly is it to implement FDM 3D printing?

This depends on the depth of implementation, the specific type of polymer that you would like to work with and the pre-existing FDM know-how in your workshop. Our FDM 3D printers range in cost from relatively inexpensive (~1k USD) machines suitable for small-size prototype production to large format professional-grade printers for up to 10k USD. The difference between low-end and high-end systems is often the build volume, the variety and quality of the materials the machine processes, and the accuracy, reliability and consistency of the system. Compared to conventional prototyping or traditional manufacturing methods such as CNC machining or injection molding, FDM printing is typically much faster and, for smaller volumes, much cheaper. As the benefits and applications grow, the technology can scale appropriately.

4. How do I effectively integrate FDM 3D printing into my production process?

As with any new technology or change in business orthodoxy, it’s worth being deliberate and planned when introducing FDM 3D printing. You may not get the results you want without a well thought out plan, or a clear strategy for a long-term, high-value return on investment. Starting small, with one or two printers for tooling, will allow your workshop team to learn about the technology, its applications and its benefits. From there, the technology can be scaled up to achieve wider adoption (replacing CNC machining) and the right benefits.

5. What is Craftware Pro?

Craftware Pro is our proprietary slicer software developed from scratch for beginners and industry experts in the field of FDM 3D printing. Download it and enjoy full slicing functionality for free of charge. Also, under various license plans, additional productivity boosting features are available that enable multi-tray slice, cut filament consumption and build time.

From the beginning, we have designed Craftware Pro’s architecture and the underpinning slicer core to be highly reusable, configurable, and extendable. This gives us a competitive edge in offering production integration services for manufacturing SMEs.

6. Why choosing to work with Craftbot is the best choice for you?

Working with the Craftbot team to produce 3D printed parts is the best way to learn about the benefits of the technology. You’ll gain the expertise and insight of a FDM printing specialist, who may be able to guide you in optimizing the use of the technology for your specific needs. Your initial outlay is usually lower as you avoid the upfront costs of completely reconfiguring a process step or integrating a new machine. Initially, our team can run proof-of-concept projects with clear goals that we set up together. When you’re confident about the positive ROI of a printing process integration of production method replacement, Craftbot completes the implementation on all levels, including printer customization, model slicing, process control, and know-how transfer via operator training.

7. How will we work together?

How will we work together?

Consider the bottlenecks of your current production line, summarize your expectations for FDM 3D printing and get an offer. Our tech team will contact you soon to know more about your current application and goals. We understand that you may avoid disclosing any relevant information, so we are ready to implement an NDA in the very early stage of our cooperation. As we agree on the goals, we may offer a proof of concept project to demonstrate our expertise before we fully engage to implement what you need.